Temperature controllers are essential devices for precise temperature control across a variety of industrial, commercial, and laboratory applications. Whether you're managing heating or cooling systems, these controllers monitor the temperature in real time and adjust power to your heating element or refrigeration unit to maintain your desired setpoint. On this page, you’ll find a carefully selected range of UK-spec temperature controllers designed to deliver accuracy, reliability, and safety in demanding environments.

Here at Under Control Instruments, our controllers are optimised to handle everything from refrigeration to high-temperature processes. With short-tail transactional intent in mind, our collection includes both on/off thermostats and more sophisticated PID (proportional-integral-derivative) controllers, giving you full control over your heating and cooling. Whether you're retrofitting an existing system or designing a new setup, our temperature controllers help you achieve optimal performance and energy efficiency.

-

Digital Thermostat 8820 with NTC Sensor – Temperature Controller -50°C to +150°C

Regular price £29.40Regular price -

Silicone Adhesive Patch K Thermocouple Sensor

Regular price £12.60Regular price -

Novus N321 Electronic Thermostat, J/K

Regular price £44.40Regular price -

Thermocouple Sensors- K probes 3mm Dia 50- 300mm lg

Regular price From £12.60Regular price -

PT100/RTD Temperature Sensors 3mm Dia

Regular price From £13.20Regular price -

½″ BSPT Thermowell Sensor Pocket – Stainless Steel

Regular price From £8.40Regular price -

PT100/RTD Temperature Sensors 6mm Dia

Regular price From £13.20Regular price -

Digital Thermostat 8820 PTC sensor

Regular price £38.40Regular price -

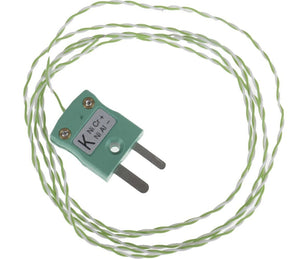

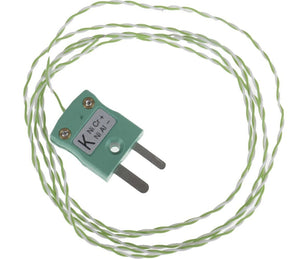

Type K Thermocouple Plug and 1.5m Exposed Tip

Regular price £5.40Regular price -

Thermocouple Sensors- K probe - 6mm Dia - 50-150mm Long

Regular price From £15.24Regular price -

N1030T PID Controller & Timer SSR/Relay Output

Regular price £48.60Regular price -

K/J Type Thermocouple Plug & Sockets

Regular price From £4.80Regular price -

N1030 PID Controller SSR/Relay Output

Regular price £54.00Regular price -

Compression Gland 316 S.ST 3/8"x 6mm BSPP

Regular price £6.00Regular price -

Novus N321 Electronic Thermostat, PT100, 12/24V

Regular price £44.40Regular price -

Novus N321 Electronic Thermostat, J/K, 12/24V

Regular price £44.40Regular price -

J/K Type Thermocouple – Thin Washer Style, 10mm OD / 6.5mm ID, 2m Leads

Regular price £11.40Regular price -

Novus N322 PID Controller PT100, 240V, Relay/Relay

Regular price £50.40Regular price -

Thermocouple Bayonet Sensor – Type J/K, 4.8 x 13mm Probe with 200mm Adjustable Spring

Regular price £12.48Regular price -

Thermocouple Sensors- J probes 3mm Dia 100- 500mm lg

Regular price From £13.80Regular price -

Leaf Thermocouple Sensor

Regular price £14.40Regular price -

Thermocouple wire type J & K

Regular price From £8.74Regular price -

Chip Scuttle Heating Element

Regular price £56.16Regular price -

60min Dial Timer Delay Switch

Regular price £15.60Regular price -

N1040 PID Temperature Controller USB

Regular price £54.00Regular price -

Thermocouple Type K 3mm x 50mm 2.5m s.st braided leads

Regular price £12.00Regular price -

Novus N1050 Relay/SSR Output PID Temperature Controller

Regular price £87.60Regular price -

Novus N322 Electronic Thermostat PT100, 240V, Relay/Relay

Regular price £50.40Regular price -

Compression Gland 316 S.ST 1/8"x 3mm BSPP

Regular price £6.00Regular price -

Compression Gland 316 S.ST 1/4"x 3mm BSPP

Regular price £6.00Regular price -

Novus N322 PID Controller J/K/T, 240V, SSR/Relay

Regular price £50.40Regular price -

Silicone Patch K Thermocouple Sensor

Regular price £14.40Regular price -

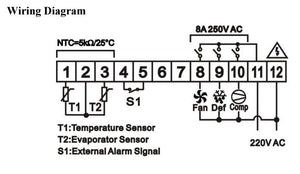

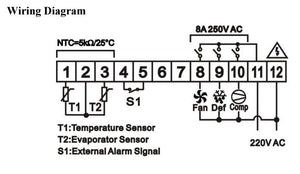

Digital Thermostat 6830 3 Outputs

Regular price £33.60Regular price -

RHT Climate Relative Humidity & Temperature Transmitter NOVUS-WM RS485

Regular price £186.00Regular price -

Din Rail USB Temperature Transmitter NOVUS TxRail-USB

Regular price £64.80Regular price -

Bench Top Temperature Control Panel

Regular price £288.00Regular price

Frequently Asked Questions (FAQs)

What is a temperature controller, and how is it different from a thermostat?

What is a temperature controller, and how is it different from a thermostat?

How do I choose between on/off control and PID control?

How do I choose between on/off control and PID control?

Which sensor type should I use (NTC, RTD, thermocouple)?

Which sensor type should I use (NTC, RTD, thermocouple)?

Can I wire a large heater to a temperature controller directly?

Can I wire a large heater to a temperature controller directly?

What safety measures should I take when using a temperature controller?

What safety measures should I take when using a temperature controller?