Infrared lamps provide a fast, efficient and reliable source of radiant heat for a wide range of industrial, commercial and specialist applications. Designed to deliver controlled infrared energy directly to the target area, these lamps heat objects and surfaces without needing to warm the surrounding air. This makes infrared lamps an ideal choice for processes that require rapid heat-up times, focused heat distribution and high energy efficiency. Our range includes a selection of infrared heat lamps, all engineered for long life, stable performance and consistent heat output.

At Under Control Instruments, we supply quality infrared heating lamps suitable for OEMs, maintenance teams, production facilities and commercial environments across the UK. Whether you're replacing a lamp in an existing system or upgrading your heating setup, our IR lamps are available in a variety of wattages, lengths, fittings and wavelengths to match your specific process requirements. With short-tail, transactional searches in mind, this category ensures you can quickly find the right infrared lamp for drying, curing, heating, food-service equipment and many other applications.

-

Ruby Infrared lamp 1400W, 230V, 348mm, R7S ends

Regular price £11.70Regular price -

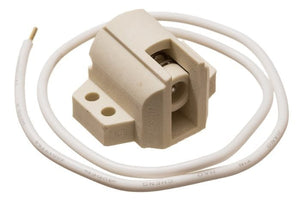

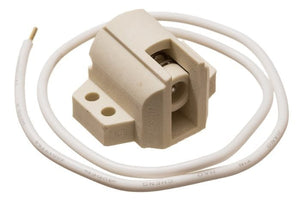

R7S Ceramic Lamp Holder (118mm)

Regular price £1.38Regular price -

Sold out

Ruby Infrared Lamp 1500W 230V – 348mm R7S Ends

Regular price £12.00Regular price -

Ruby Infrared Lamps 118-R7S – Long-Life Replacement for Parasol Heaters

Regular price From £3.60Regular price -

Clear Infrared 118-R7S Catering Lamps

Regular price From £3.97Regular price -

Birchwood Rhino TQ3 R7s End Lamp Fittings – 2 Pack

Regular price £9.60Regular price -

R7S Ceramic Lamp Holder – Model R7S-806AT (2 Pack)

Regular price £5.99Regular price -

Ruby Infrared lamp 1400W, 110V, 348mm, R7S ends

Regular price £11.70Regular price -

Ruby Infrared Lamp 1.5kW 240V – 350mm SK15 Ends

Regular price £11.70Regular price -

Ruby Infrared lamp 1000W, 240V, 350mm SK15 ends

Regular price £12.00Regular price -

Sold out

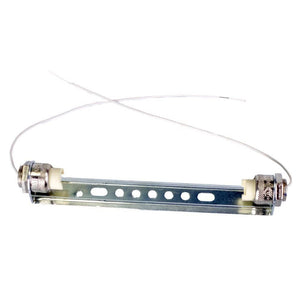

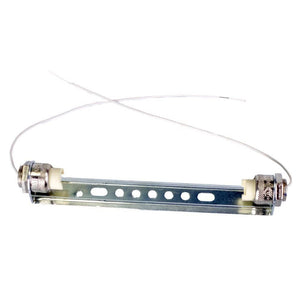

R7S Alloy lamp holder R7S-804AT (pair)

Regular price £3.84Regular price -

Ruby Infrared lamp 1100W, 230V, 348mm, R7S ends

Regular price £13.20Regular price -

E27 Ceramic Lamp Holder

Regular price £2.39Regular price -

Ruby Infrared lamp 1100W, 110V, 348mm, R7S ends

Regular price £13.80Regular price -

Lampholder and Reflector for 220mm Catering Lamp

Regular price £10.80Regular price -

Ruby Infrared lamp 1300W, 230V, 254mm, R7S ends

Regular price £9.94Regular price -

Lamp Holder-118 R7S Flat Bar

Regular price From £1.92Regular price -

LINCAT LA210 Infrared Gantry Lamp – 220mm, 500W, R7S

Regular price £12.00Regular price -

Gold Infrared Lamp 1500W 240V 350mm SK15 Ends – GIR-1.5KW-350-SK15-7960227

Regular price £23.52Regular price -

Ruby Infrared lamp 1000W, 230V, 254mm, R7S ends

Regular price £9.94Regular price -

Ruby Infrared Lamp 1500W 110V – 348mm R7S Ends

Regular price £11.70Regular price -

Clear Infrared 216-SK15 Heat Lamp

Regular price From £9.60Regular price -

Gold Infrared Lamp 500W 230V 118mm R7S Ends – GIR-500W-118-R7S-7960221

Regular price £9.60Regular price -

Ruby Infrared Lamp 1000W 530-SK15

Regular price £27.55Regular price -

E27 Ceramic Lamp Holder – 3 Pack

Regular price £5.10Regular price -

Ruby Infrared lamp 1200W, 230V, 254mm, R7S ends

Regular price £9.94Regular price -

Gold Infrared Lamp 2000W 240V 350mm SK15 Ends – 7960277

Regular price £23.16Regular price -

Gold Infrared Lamp 400W, 230V, 118mm R7S ends

Regular price £9.60Regular price -

Ruby Jacketed Infrared Lamp – 1500W, 240V, 350mm OAL, SK15

Regular price £26.40Regular price -

Ruby Infrared lamp 2000W, 240V, 350mm SK15 ends

Regular price £12.19Regular price -

Sold out

Gold Infrared Lamp 1000W 240V 350mm SK15 Ends – 7960280

Regular price £23.09Regular price -

Ruby Infrared lamp 2000W, 230V, 348mm, R7S ends

Regular price £13.20Regular price -

Ruby Infrared lamp 1000W, 110V, 348mm, R7S ends

Regular price £12.19Regular price -

Ruby Jacketed 300W Infrared Lamps 118-R7S

Regular price £12.00Regular price -

Infrared Heat Lamp Clear 500w 254mm R7S ends

Regular price £8.44Regular price -

Infrared Short Wave Heating Lamp – X-Strap Clear Tube

Regular price From £10.01Regular price

Frequently Asked Questions (FAQs)

What is an infrared lamp used for?

What is an infrared lamp used for?

What is the difference between an infrared lamp and a standard heat lamp?

What is the difference between an infrared lamp and a standard heat lamp?

How long do infrared heating lamps last?

How long do infrared heating lamps last?

Can infrared lamps be used for industrial processes?

Can infrared lamps be used for industrial processes?

Are infrared lamps safe to use?

Are infrared lamps safe to use?