PEL gas valves are the industry standard for reliable, safe gas flow control in commercial and catering applications. Whether you're searching for a robust PEL Gas Valve replacement for a wok cooker, griddle, or high-output burner, our curated range ensures that you get genuine, certified components compatible with LPG and natural gas installs. At Under Control Instruments, we stock a broad selection of PEL Gas Valves, offering flame-failure safety, vertical or horizontal mounting, and compression or threaded connections.

With fast UK shipping on orders over £25 and technical support from gas experts, selecting the right PEL gas valve has never been simpler. Our inventory includes the most common models (such as 20S, 21S, 22S/O, 23S), as well as replacement parts like knobs and magnets. Whether you're completing a routine service or designing a new gas system, our PEL Gas Valves provide precision control, regulatory compliance, and peace of mind.

-

PEL Valve Knobs

Regular price £4.20Regular price -

PEL 21S 7988B-7 Gas Control Valve Flame Supervision FSD/FFD

Regular price £36.00Regular price -

Save £4.80

Shaan Tandoor Safety Valve

Regular price £25.20Regular price£30.00-£4.80 Sale price £25.20 -

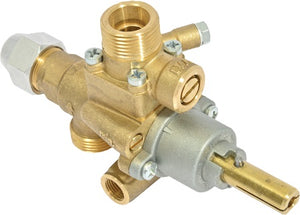

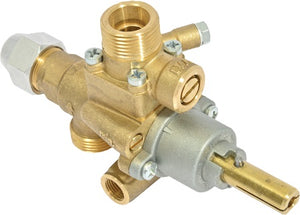

Gas Valve 22S/O - PEL 791911

Regular price £60.00Regular price -

PEL Valve Handles 22/23S

Regular price £6.60Regular price -

PEL 21S 7988B-7 Gas Control Valve Threaded Collar

Regular price From £33.60Regular price -

Gas Valve PEL 22S/O Replacement

Regular price £46.80Regular price -

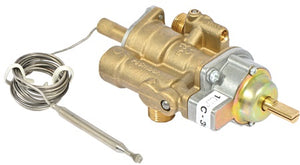

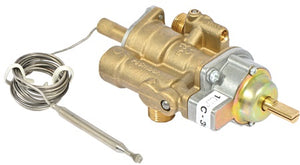

PEL 20/S 7989B Griddle Control Valve FSD/FFD Replacement

Regular price £27.00Regular price -

Sold out

Replacement PEL 22S/V Flame Failure Gas Control Valve – Vertical Installation

Regular price £57.60Regular price -

Replacement PEL 22S Flame Failure Gas Control Valve Horizontal

Regular price £57.60Regular price -

PEL 23S Flame Failure Safety Gas Valve With Fittings Kit

Regular price £109.20Regular price -

22S PEL Nuts & Olives

Regular price £3.00Regular price -

22S/V PEL 791804 Gas Control Valve

Regular price £60.00Regular price -

PEL 24ST Gas Control Thermostat

Regular price £118.56Regular price -

Replacement 22S/V PEL Gas Control Valve

Regular price £54.00Regular price -

PEL 25ST Gas Control Thermostat Replacement – Precision Temperature Control

Regular price £117.60Regular price -

Electrolux 0C8647 Safety Gas Tap

Regular price £150.00Regular price -

ELECTROLUX ZANUSSI GAS CONTROL VALVE 004237

Regular price £37.99Regular price -

Replacement 22S/O Horizontal PEL Gas Control Valve

Regular price £57.60Regular price -

Save £4.80

MA09 PEL 23 23S FFD FSD REPLACEMENT VALVE MAGNET

Regular price £18.00Regular price£22.80-£4.80 Sale price £18.00 -

ELECTROLUX ZANUSSI GAS VALVE TAP 052146

Regular price £80.40Regular price -

ELECTROLUX ZANUSSI GAS CONTROL VALVE 059460 FSD/FFD

Regular price £77.40Regular price

Frequently Asked Questions (FAQs)

What is a PEL gas valve and how does it differ from ordinary gas valves?

What is a PEL gas valve and how does it differ from ordinary gas valves?

Can I use PEL gas valves for both LPG and natural gas?

Can I use PEL gas valves for both LPG and natural gas?

How do I choose between PEL 22S (horizontal) and 22S/V (vertical)?

How do I choose between PEL 22S (horizontal) and 22S/V (vertical)?

What happens if the pilot flame goes out - how do these valves respond?

What happens if the pilot flame goes out - how do these valves respond?

Do I need to reset a PEL valve after a flame failure?

Do I need to reset a PEL valve after a flame failure?