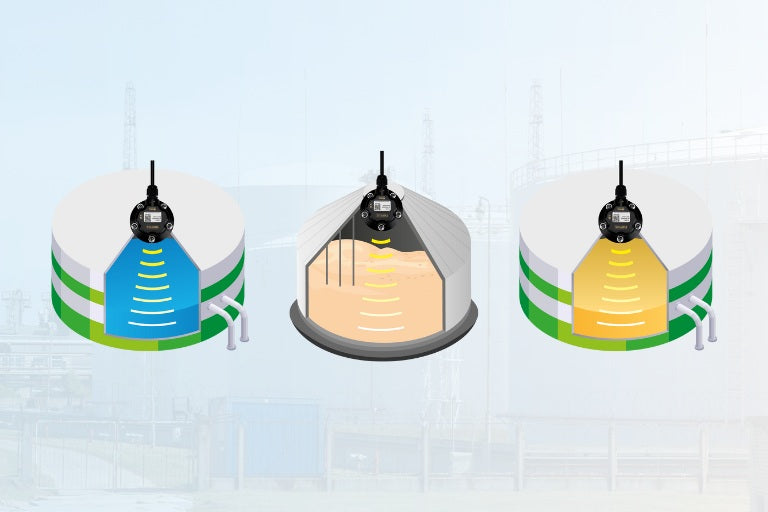

Accurate level measurement is essential in modern industry, from managing storage tanks to monitoring liquids in production systems. While some level transmitters are immersed directly in the medium, three main non-contact technologies dominate the market: ultrasonic, radar, and laser.

Each has unique advantages and limitations. Choosing the right one depends on your application, environment, and performance requirements.

Ultrasonic Level Measurement

Best for: Simple, low-cost applications.

Ultrasonic transmitters use high-frequency sound waves to calculate the distance between the sensor and the surface of a liquid or solid.

✅ Advantages:

-

Cost-effective solution for straightforward applications.

-

Easy to install and maintain.

-

Suitable for both liquids and bulk solids.

⚠️ Limitations:

-

Limited measuring range with a “dead zone” directly below the sensor.

-

Susceptible to interference from other acoustic equipment.

-

Requires regular cleaning to prevent dirt buildup affecting accuracy.

Radar Level Measurement

Best for: Large tanks and harsh environments.

Radar transmitters use electromagnetic waves to determine the distance to the surface. This makes them more reliable than ultrasonic devices in challenging conditions such as extreme temperatures, pressure, or vapor.

✅ Advantages:

-

Highly accurate and reliable in demanding environments.

-

Not affected by temperature, pressure, or vapor.

-

Well-suited for large storage tanks.

⚠️ Limitations:

-

Higher initial investment.

-

Requires technically skilled configuration.

-

Can be affected by internal tank obstructions that reflect radar signals.

Laser Level Measurement

Best for: High precision and real-time monitoring.

Laser transmitters provide instant, highly accurate measurements and are relatively simple to install. They combine some of the affordability of ultrasonic technology with accuracy closer to radar.

✅ Advantages:

-

Exceptional accuracy and fast response.

-

Real-time monitoring capability.

-

Quick and straightforward installation.

-

Flexible for diverse applications.

⚠️ Limitations:

-

Can be affected by dust, vapor, or condensation in the beam path.

-

Typically more expensive than ultrasonic devices.

Choosing the Right Technology

-

Ultrasonic: Ideal for less complex, budget-conscious applications.

-

Radar: Best choice for harsh or large-scale environments.

-

Laser: Recommended when precision and flexibility are critical.

Final Thoughts

The right level transmitter is vital for ensuring operational efficiency and safety in industrial processes. Evaluate the strengths and weaknesses of each technology against the specific needs of your application.

With careful selection and proper implementation, your business can achieve accurate measurement, reduced downtime, and improved process control.